Local economy

What will be the long-term employment impact of the project on the local economy?

When we are fully operational, we expect to need around 350 extra direct employees, we hope to fill most of these roles with local workers. Add to this the indirect employment benefit (e.g. maintenance contractors and other subcontracted activities, up to a factor of eight) the positive impact to the local economy will be significant.

Will construction workers be housed locally during the building of the processing plant?

A 'temporary village’ will be created for construction workers on Imerys land, when we are building the processing plant as the plant will need some specialist skills not available locally, details will be provided in our planning application.

What training opportunities will be available through the project?

We are already considering what training courses will be developed with our local education partners. This presents a fantastic opportunity for many Cornish people.

How many jobs will the full-scale lithium project create, and who can benefit from them?

We expect to need around 350 new full time employees for the full scale project and many more will be required during the construction phase. This creates opportunities for local residents, especially young people who will be able to train under newly developed apprenticeships and other courses.

Water

How do you manage water usage and contamination in your production process?

As our unique process uses minimal chemicals, we can recycle water easily back into the process, and we will only release fully treated water

Does the lithium project use a lot of water or impact local water supplies?

The proposed lithium operation recycles all the water it uses, with a small net demand. Imerys has significant water supplies across its estate meaning it does not draw from public resources.

Environment

How will the project ensure a net gain in biodiversity during the planning process?

To achieve a positive outcome in the planning process, the project will need to prove a net gain in biodiversity (i.e. the delivery of the project will mean a net positive impact on the variety and variability of plants/animal species in the near vicinity of the sites).

We will deliver at least a 10% increase in biodiversity value compared to the pre-development state, either by enhancing existing habitats on-site or creating new ones off-site. This gain will be maintained for at least 30 years.

How will you minimise your impact on the local environment and communities?

We will work closely with Cornwall Council, Natural England, Historic England and local charities such as Cornwall Wildlife Trust to minimise impact on the environment, wildlife and historic environment. We will also engage with the local communities in this area and take on board as many opinions and as much local knowledge as possible.

What impact will the plant have on the environment, wildlife and land including ancient monuments etc?

The processing plant and quarry are to be located within an existing Imerys kaolin quarry. The surrounding area has been quarried for hundreds of years. Imerys has over the years developed close relationships with local communities affected by mining works and has a good track record of acting on any concerns or problems, quickly and effectively. We will continue to work in this way.

Diesel usage

How does your mining design reduce fuel consumption and carbon emissions?

Our mine design reduces fuel consumption and carbon emissions in two key ways.

Firstly, we are engineering the mine to minimise 'vertical lift' - the steep, uphill haul that burns the most fuel in a typical quarry. By creating smarter, more efficient routes, we are able to cut diesel use.

Second, our plan reduces our footprint by excavating the lowest possible volume of overburden rock (the rock that sits above the lithium bearing ore). A large portion of this overburden material is historic tipped rock from old quarry workings, which we will use to restore a neighboring disused quarry, helping to return a past industrial site to a more natural landscape.

Furthermore, we are actively partnering with major equipment suppliers who are developing the next generation of low-carbon equipment such as electric loaders (diggers), electric haul trucks (battery operated), and alternative fuels, so we can integrate these technologies as they are proven.

Lithium

Why is the UK government supporting lithium production projects like this one?

Securing a UK supply is essential as we progress on our journey towards Net Zero. This will protect the UK from the effects of global instability and price fluctuations. Globally, we need more lithium than is currently available, and none is currently produced in Europe, which is why the UK government is supporting our project.

Why does the cost of UK lithium production need to be competitive?

It will be important for the cost of UK production of lithium to be competitive, so that we can reliably supply customers over the long term, and justify the major investment required.

Why is a domestic supply of lithium important for the UK and EU?

Lithium pricing has been very volatile over the past few years. But as the UK and EU’s deadline to switch sales of new vehicles to EVs is only 10 years away, and the UK continues on its journey to net zero - the need for a domestic supply of lithium is projected to increase strongly.

Waste streams

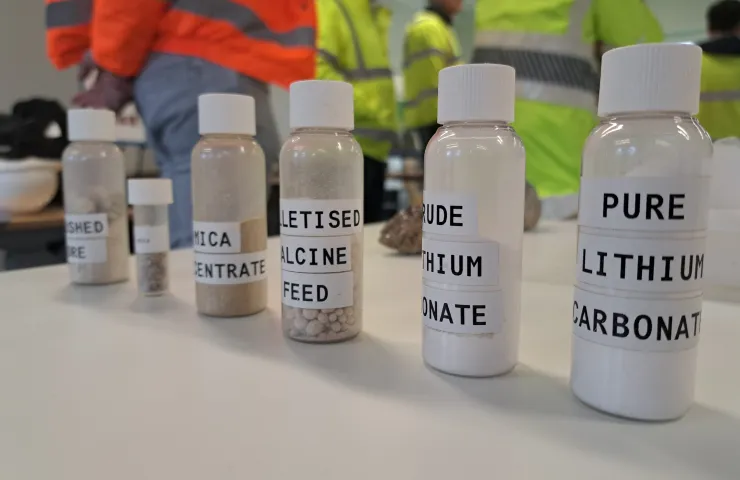

What waste streams will be produced?

Overburden:

Excavated granite which does not contain lithium bearing mica will be deposited within a historic mining void. Similar to existing kaolin operations, this material will be assessed to determine if in the future commercially viable secondary aggregates or if other minerals products can be extracted.

Residue materials produced during beneficiation:

Crushed granite is ground to a fine sand size with the lithium bearing mica separated using electromagnets. The remnant materials are known as 'tailings' - produced as a slurry and characterised as inert.

These tailings will be deposited into historic mining voids - that is - spent kaolin pits. Backfilling old pits is the first step of restoring the land over the long-term.

We are looking at ways to determine if - in the future - other commercially viable minerals products can be extracted from these residue materials. This would reduce the quantities of materials returning into the ground.

Residue materials produced during upgrading of the lithium:

The mica concentrate is then roasted with reagents including gypsum and limestone to convert the lithium into a water-soluble form. Soluble lithium is then upgraded to produce battery grade lithium carbonate.

'Mineral Extraction Residues' are left over after the lithium has been extracted. These residues will be deposited into an historic mining void from kaolin operations. This engineered mining residue facility ensures the landform remains safe, stable and doesn’t pose a risk to the environment over the long-term.

The regulatory framework for monitoring mining residue facilities is comprehensive and the systems put in place will be subject to regular audits and controls by the relevant regulatory authorities.

Blasting

Will the project have any negative impact on local communities or amenities?

We have been undertaking background noise and other assessments to ensure there will be no adverse effect on local amenities or communities.

Will the project impact nearby homes or the surrounding landscape?

This will be at depth below ground level and the site maintains a substantial landscape buffer that separates the site from any nearby sensitive properties or neighbours to ensure there is no adverse impact outside of the site.

How will the ore be extracted from the quarry?

Within the quarry, the ore will be extracted by a combination of blasting, bulldozer and excavator following proven techniques that are already operated by Imerys and that are fully contained within the pit.

Is there any seismic impact from blasting?

We are already blasting in this area for our kaolin activities and so we will continue to work in the same way, with the same Imerys team managing the process following strict guidelines.

Do you still have questions?

We look forward to hearing from you, so please don't hesitate to contact us.