Overburden

Excavated granite which does not contain lithium bearing mica will be deposited within a historic mining void. Similar to existing kaolin operations, this material will be assessed to determine if in the future commercially viable secondary aggregates or if other minerals products can be extracted.

Residue materials produced during beneficiation

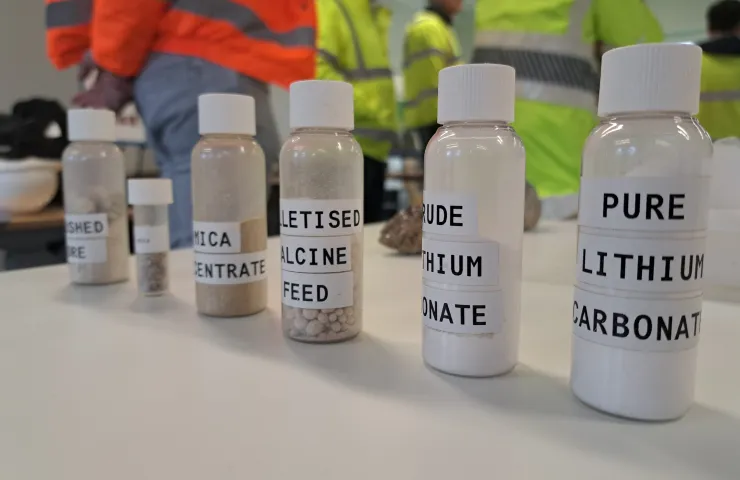

Crushed granite is ground to a fine sand size with the lithium bearing mica separated using electromagnets. The remnant materials are known as 'tailings' - produced as a slurry and characterised as inert. These tailings will be deposited into historic mining voids - that is - spent kaolin pits. Backfilling old pits is the first step of restoring the land over the long-term.

We are looking at ways to determine if - in the future - other commercially viable minerals products can be extracted from these residue materials. This would reduce the quantities of materials returning into the ground.

Residue materials produced during upgrading of the lithium

The mica concentrate is then roasted with reagents including gypsum and limestone to convert the lithium into a water-soluble form. Soluble lithium is then upgraded to produce battery grade lithium carbonate. 'Mineral Extraction Residues' are left over after the lithium has been extracted. These residues will be deposited into an historic mining void from kaolin operations. This engineered mining residue facility ensures the landform remains safe, stable and doesn’t pose a risk to the environment over the long-term. The regulatory framework for monitoring mining residue facilities is comprehensive and the systems put in place will be subject to regular audits and controls by the relevant regulatory authorities.

Long-term stability

One hundred percent of tailings and mineral extraction residues will be deposited in historic pits - removing the need for above ground structures.

Reuse

Additional land disturbance avoided by reusing historic pits - more than 140 hectares

Restoration

We have the opportunity to create four reserves due to back filling old pits - including wetland features and habitats

Your Questions about waste

What waste streams will be produced?

Excavated granite which does not contain lithium bearing mica will be deposited within a historic mining void. Similar to existing kaolin operations, this material will be assessed to determine if in the future commercially viable secondary aggregates or if other minerals products can be extracted.

Residue materials produced during beneficiation:

Crushed granite is ground to a fine sand size with the lithium bearing mica separated using electromagnets. The remnant materials are known as 'tailings' - produced as a slurry and characterised as inert.

These tailings will be deposited into historic mining voids - that is - spent kaolin pits. Backfilling old pits is the first step of restoring the land over the long-term.

We are looking at ways to determine if - in the future - other commercially viable minerals products can be extracted from these residue materials. This would reduce the quantities of materials returning into the ground.

Residue materials produced during upgrading of the lithium:

The mica concentrate is then roasted with reagents including gypsum and limestone to convert the lithium into a water-soluble form. Soluble lithium is then upgraded to produce battery grade lithium carbonate.

'Mineral Extraction Residues' are left over after the lithium has been extracted. These residues will be deposited into an historic mining void from kaolin operations. This engineered mining residue facility ensures the landform remains safe, stable and doesn’t pose a risk to the environment over the long-term.

The regulatory framework for monitoring mining residue facilities is comprehensive and the systems put in place will be subject to regular audits and controls by the relevant regulatory authorities.